PI has more than doubled its manufacturing floor space in the United States with the opening of its all-new 70,000 sq.ft. production facility in Irvine, CA.

Following its acquisition of BIT’s North American operations in 2021, PI, who design and manufacture medical devices, life science instruments and diagnostic instruments, had approximately 29,000 sq. ft. of manufacturing space in the United States.

The new Irvine site signifies PI’s long-term commitment to becoming one of the United States’ premier medical device manufacturing companies, with over 70,000 sq. ft. of ISO-13485 certified facilities including specialist wet lab environments for manipulating liquids, biological matter, and chemicals.

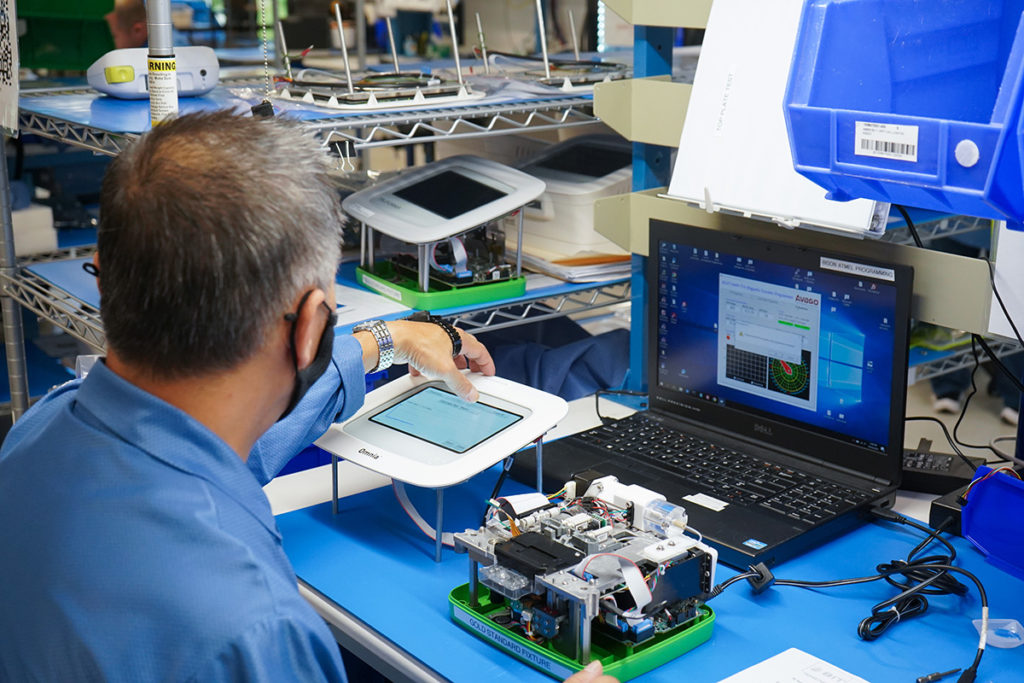

PI currently manufactures approximately 30 different regulated medical devices and consumable products ranging from small, hand-held instruments through to large, complex floor-standing instruments. PI’s global manufacturing footprint, which includes two facilities in Australia, now totals more than 120,000 sq. ft. (11,150 sq. m.).

PI CEO, Stuart Elliott, said that the opening of PI’s Irvine facility marked an important milestone for the company. “Over 70 percent of our clients are in the United States, so it’s critical that we have a large, fully equipped manufacturing facility on their doorstep. Whether it’s manufacturing a brand-new device that we helped design, or an existing instrument they already have on the market, PI brings a new level of responsiveness and accountability to our clients. Because PI provides our clients with a unique end-to-end range of development through to manufacturing services, we operate as a one-stop-shop for our clients who in turn appreciate having a single partner taking full responsibility for the production and delivery of their products,” he said.

In addition to its expansive production space, PI’s manufacturing sites include a range of highly specialized facilities including ISO Class 7 cleanrooms, wet labs, science labs, reliability labs and optics labs.

PI’s Irvine-based Global Head of Quality, Krystal Santiago, said: “At PI, the products that we build are more than just innovative – they are of the highest quality. Our commercial mindset means that PI always aims to provide its clients with the quickest time-to-market and, most importantly, the highest build standard. Our quality systems and disciplined culture provide a relentless focus on delivering exceptional levels of efficiency and customer service.”

Planet Innovation’s strategy is to build at-scale manufacturing facilities in both the United States and Australia so it can serve both markets with maximum effectiveness and provide a dual-source manufacturing offering for its clients. This flexible offering combats global supply chain risk, which is of particular importance for mission-critical products such as medical devices.

Contact us to discuss how Planet Innovation’s manufacturing offerings can help your business.