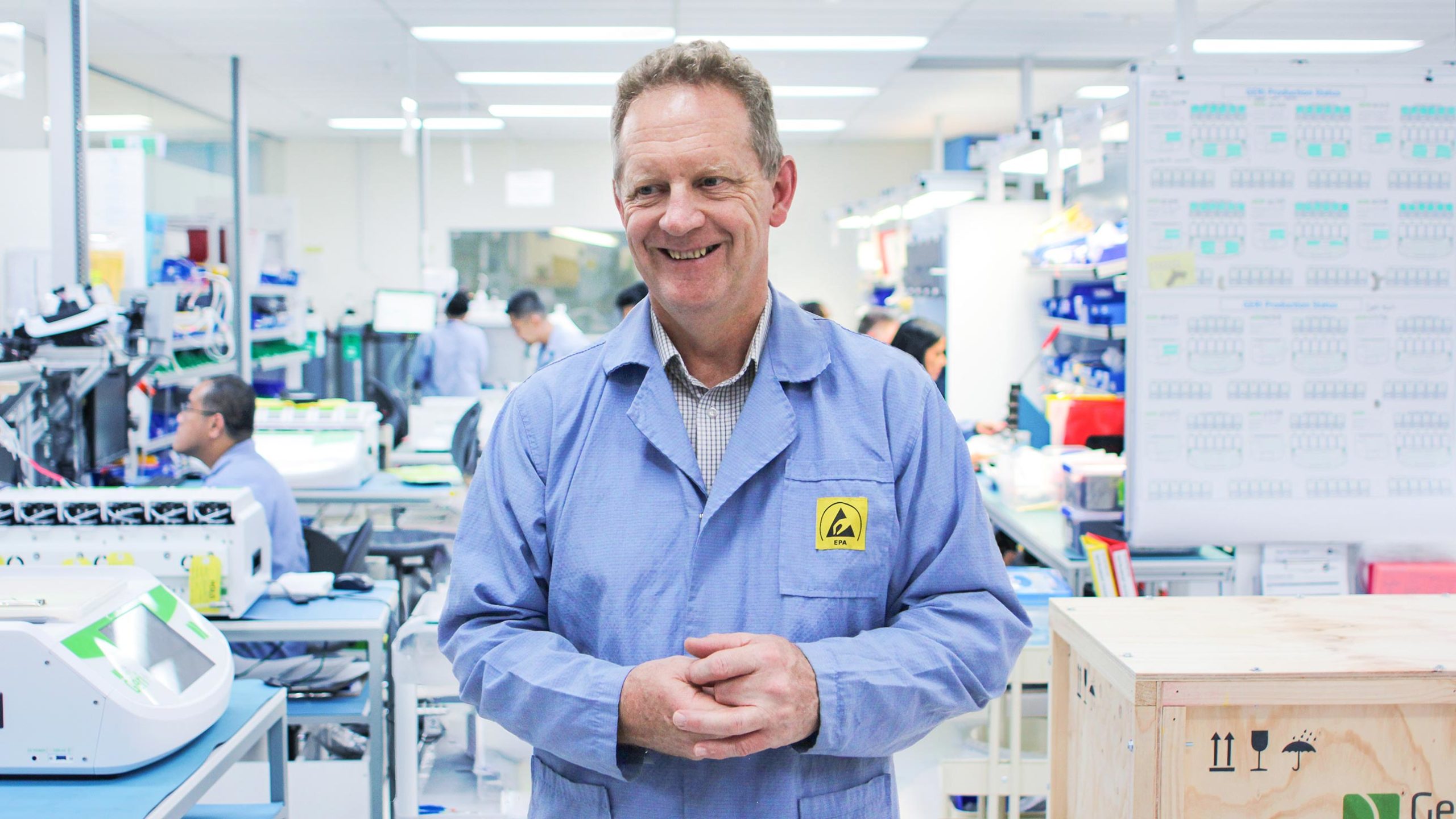

What sets one contract manufacturing operation apart from another? According to Colin Potter, Planet Innovation’s General Manager of Manufacturing, it’s all about shared values and aspirations between manufacturer and clients.

As the General Manager of PI Manufacturing, Colin Potter brings almost 40 years’ experience to his role. He knows what makes new products successful. A trained mechanical engineer, he initially worked in product design and development, translating clients’ ideas into working prototypes. Colin then shifted focus to the art and science of contract manufacturing, taking prototypes into mass production.

So, when Colin joined Planet Innovation in 2012, he arrived with clear ideas about the success factors needed to distinguish Planet Innovation’s manufacturing service from competitors. He set about embedding these success factors across his entire manufacturing team, which now employs more than 60 full-time staff.

Regulated product manufacturing

Planet Innovation’s clients include developers of complex biomedical systems, as well as designers of consumer products. Since Planet Innovation offers regulated product manufacturing, it has achieved ISO 13485:2016 and ISO 9001 certification for its main manufacturing facility and is registered with the FDA (United States Food and Drug Administration). It’s recently opened an ISO 7 certified cleanroom for manufacturing sterile consumables. These quality assurance systems are an essential part of Planet Innovation’s manufacturing service, as clients know they can trust that their products will be produced to standard.

But success is not solely about capability and compliance, Colin says. It is about shared values and aspirations. The three most critical are:

- collaboration

- communication

- transparency

Collaboration

Colin’s background makes him a great collaborator. He understands designers because he was one. He understands manufacturers because he is one. For clients, he decodes the language of the engineering experts. He (or one of his team) sits in on meetings between the client and designers at the earliest possible stage – ideally at concept and feasibility discussions.

Why? “When we get involved early, our clients end up with a seamless transition from design into manufacturing,” Colin says. “Why does that matter? Because the decisions you make early in a design impact you forever in the product.”

It may sound incredible, but the choice and placement of a single screw can impact the cost of manufacturing. It might be hard to source, or expensive to buy. Its placement might make the product more difficult to assemble. And, when products sometimes involve hundreds, occasionally thousands, of components, catching those decisions early becomes a ‘no-brainer’, says Colin. That’s why PI manufacturers work closely with designers to ensure they are designing for manufacturability and assembly.

Communication

Great collaboration demands great communication, another value that Colin has brought to manufacturing at PI. Both design and manufacturing are problem-solving disciplines. Product development itself is about solving a problem for a particular market. Yet many great products fail because of poor communication over problems, Colin says. He knows why. Money is at risk. Expectations vary. Emotions run high. Colin’s answer was to build a dedicated team of Product Support Managers at PI. Their job is to respond quickly to customer queries, to foster good communication between the engineering disciplines (industrial designers, mechanical, electrical and software engineers) and quickly solve any problems that arise.

“Our skills are broad. We have product support managers from mechanical and electronic backgrounds. They’re capable in both disciplines and familiar with software engineering and how to integrate that into a product. We offer a broad understanding that supports the product.”

These multidisciplinary product support managers are one of the elements that sets PI apart from low-cost competitors across Asia, Mexico and even Europe, Colin says.

“Across the low-cost regions, the skillset tends to be vertical. Your product support manager may have a strong understanding in mechanical engineering, but if you ask them anything to do with electronics or software, the answer is, ‘I don’t know. You need to talk to them.’ Pretty soon, you have three people involved in a problem.”

Transparency

Collaboration and communication are based on trust. And nothing undermines trust faster than arguments over money. But how to get around them?

Colin is a proponent of “open-book manufacturing”. He opens Planet Innovation’s books to its clients and takes them through the labor and material costs and the company’s profit margins. This financial transparency between client and contractor is known as open-book manufacturing.

When a manufacturer’s books are closed to clients, risks abound. Clients worry they are being ripped off. Manufacturers have no incentive to reduce costs. If they do save costs (most manufacturing processes become more efficient over time) they have no incentive to share the savings with clients.

Open-book manufacturing, on the other hand, builds trust between client and contractor, Colin says. Clients stop worrying about being overcharged. Instead, both parties collaborate on reducing costs and maximizing product sales, ultimately leading to increased profits.

Results

Making new products is a high-pressure game, but for Colin, it’s all in a day’s work. The answer lies in deciding on a process and sticking to it. Simple as that.

It’s the outcome that makes it all worthwhile. Colin says: “Manufacturing is the implementation of all of the hard work you go through in a design process. It’s all theoretical until you are manufacturing and selling a product. We’re making the products that our clients sell, and those products help people.”

__________________

Bio in brief: Colin Potter, GM – PI Manufacturing

Expertise

Qualified mechanical engineer with almost 40 years of product development and manufacturing leadership experience.

Pleasures outside work

Mountain-bike riding, and cycling to work

Best career advice I’ve ever had

When it comes to leadership, step up and believe in yourself, and seek out good advice.

Find out more about PI Manufacturing