Mechanical Engineering

Turning client core-tech and PI technical know-how into commercial reality.

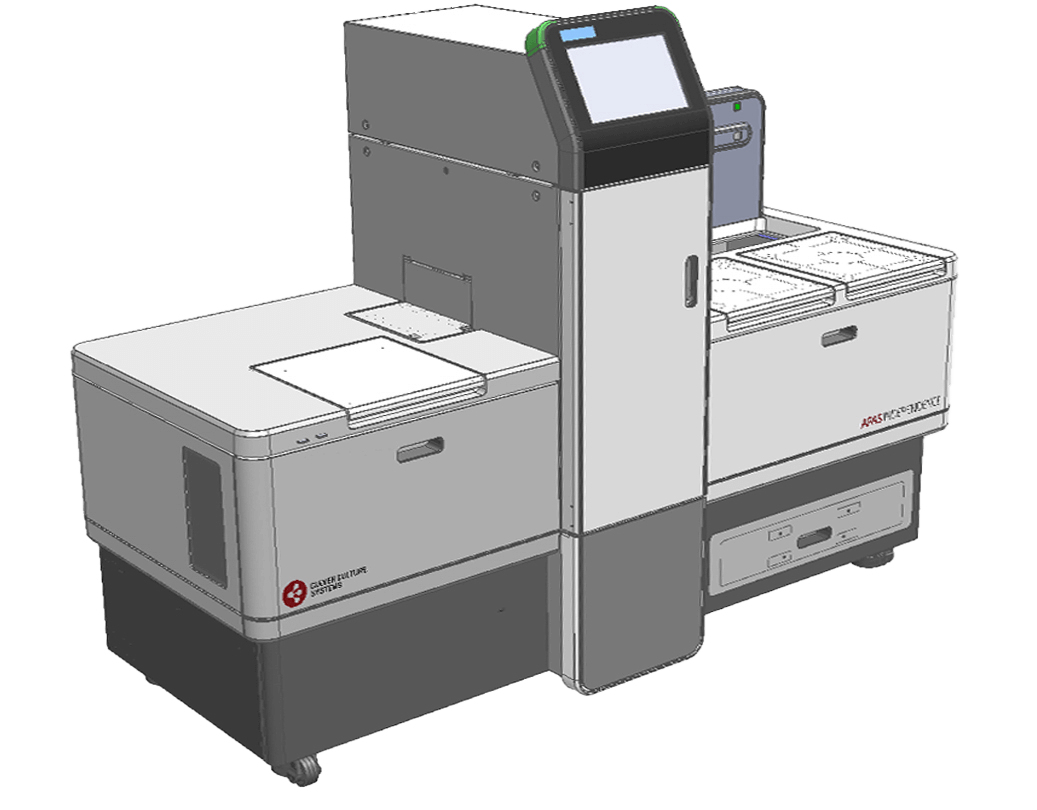

The mechanical design team draws on decades of expertise in medtech and other regulated industries to guide the realization of complex and novel products, leveraging world-class tools, proven manufacturing processes and PI’s proprietary innovation methods to deliver commercial success.

We work collaboratively with all stakeholders to deliver exactly what is required for the product’s success at every point in PI’s phased development process. These outputs range from initial concepts and architectures, through prototypes of varying complexity for specific testing and verification purposes, to the transfer of complete mechanical development data packs to support volume production.

Product Definition

Concept Development

New product development is an inherently ambiguous endeavor. Successfully navigating this uncertainty relies on the robustness of the design concept. A culture of practical innovation exemplified by PI’s proprietary BRIGHT innovation process underpins the development of product concepts that are resilient to evolving demands, and extensive experience in dynamic project conditions keeps team members pragmatic and results-oriented as situations change.

Development Strategy

At PI, we are focused on delivering the most effective and efficient development solutions to our clients’ technical and commercial needs. We apply a strategic lens to the development program that leverages our comprehensive in-house mechanical development skills and tools, as well as trusted supply-chain partners to ensure our development strategy is aligned with our clients’ needs.

Feasibility

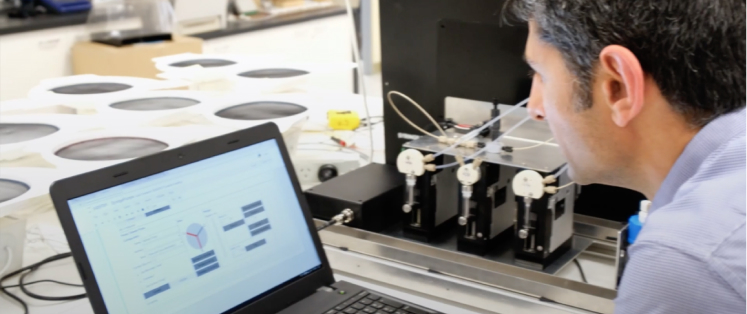

The “start small, fail fast” philosophy guides Planet Innovation through the early design phases, and the Mechanical Design team drives the development of quick, low-budget Proof of Principle test rigs to test the core-tech and key concept design elements prior to starting detail design. More complex Concept Demonstrator Prototypes (CDPs) and Integrated Test Rigs (ITRs) extend this risk-reduction testing approach to the overall product concept and to the client’s assay/consumable performance.

Prototyping Capabilities

The Mechanical Design team relies on both in-house and proven third-party prototyping capabilities as appropriate for different levels of testing. Extensive in-house 3D printing, laser cutting, CNC machining and pneumatic/fluidic prototyping capabilities support very fast turn-arounds for early-stage prototyping, while low-volume production-quality suppliers are used for reliability and verification testing of production-intent designs.

Design for Excellence

PI brings concepts to production-ready reality through a development process that embeds Design-for-Excellence (DFX) philosophies. Close collaboration with component and final assembly providers – either from PI’s own network or the client’s – supports Design for Manufacturing and Assembly goals from design concept onwards, with particular emphasis in Alpha and Beta phases. Design for Reliability, Development Cost, Product Cost and Time To Market are other standard PI DFX considerations, with the relative emphasis of each adjusted according to the client’s individual definition of “excellence”.

Design to Production

As part of a full-service development partner, the PI Mechanical Design team produces all the necessary product documentation to support series production. This includes high-quality part and vendor-assembly drawings with ASME-standard dimensioning to meet the inspection and approval demands of ISO 13485. PI runs Solidworks CAD within a Solidworks Enterprise PDM environment, and can operate independently or integrate with client CAD/PDM systems as desired to produce drawings that meet the client’s internal quality-system and ERP needs.

Related Capabilities

Our specialist systems engineering group is responsible for managing all the interfaces between the development groups. This begins at the early stages of developing project requirements and continues throughout the project monitoring key risks and performing in depth testing.

PI’s electronic engineering team is highly capable in the design of complex electronics for medical devices including: system architecture, schematic & PCB layout using Altium designer, loom design, prototyping, assembly and transfer to manufacture.

The software team at Planet Innovation has a broad range of experience developing software for medical devices, and other domains. We apply software development best practices such as Agile Development, Continuous Integration and Test Driven Design.