Optics

Experts in the design and manufacture of optical systems for the regulated medical device industry and beyond.

Planet Innovation offers targeted optics support for your product, with a dedicated team of optics and opto-mechanical specialists who have demonstrated capability in developing and manufacturing integrated optical systems for medical instruments.

Our specialists work closely with you to understand your business needs and product requirements during all phases of the product development lifecycle, ensuring delivery of the most efficient, highest performing optical solutions to achieve commercial success.

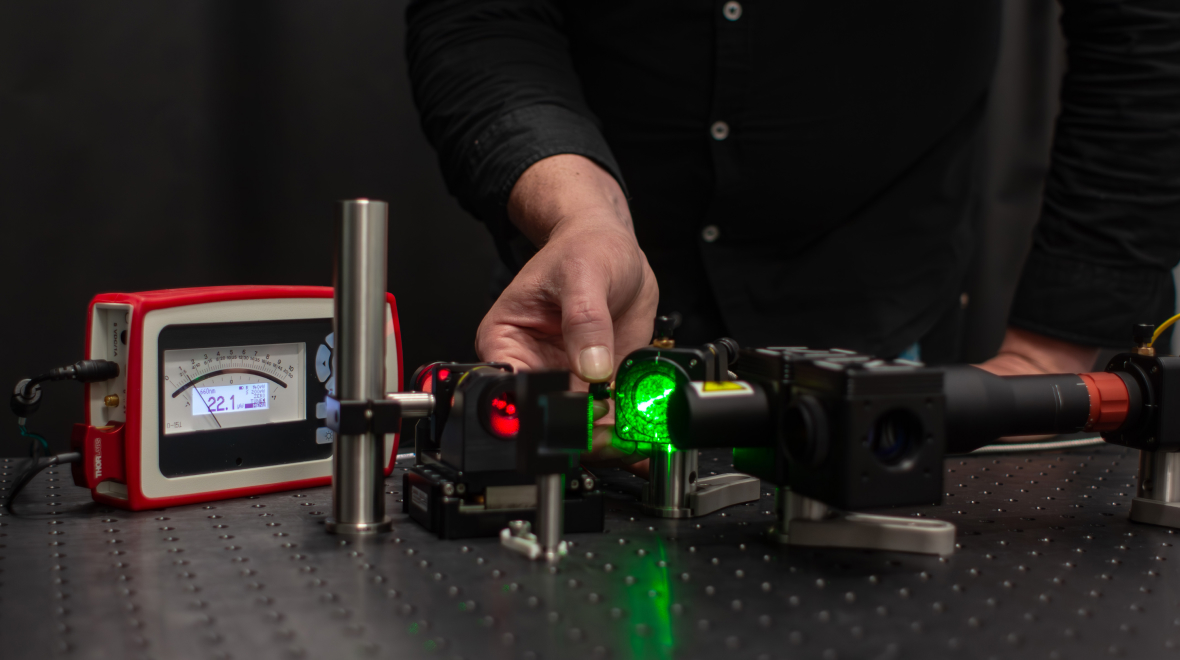

Radiometry for Medical Devices

We are experienced in developing a wide range of medical devices incorporating digital imaging, microscopy, and radiometry using both off-the-shelf and custom designed opto-mechanical assemblies, including:

- Macro imaging

- Confocal microscopy, both wide-field and epifluorescence

- UV, VIS, and NIR spectroscopy

- Fluorescence- or size-activated cell and droplet sorting (FACS and FADS)

- Colorimetry

- Incorporation of silicon photonics biosensors into consumables

Optical Analytical Methods

A wide range of image acquisition and processing methods are available to meet the specific analytical needs of your optical system:

- Imaging (colorimetry or fluorescence intensity for quantification of assay concentration)

- Real-time iso-thermal amplification or PCR growth curves

- Digital PCR

- AI/ML

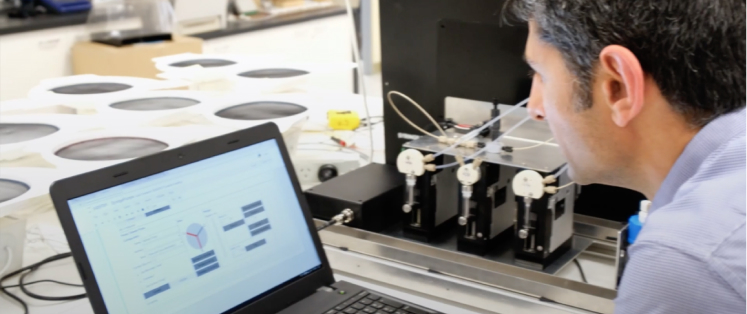

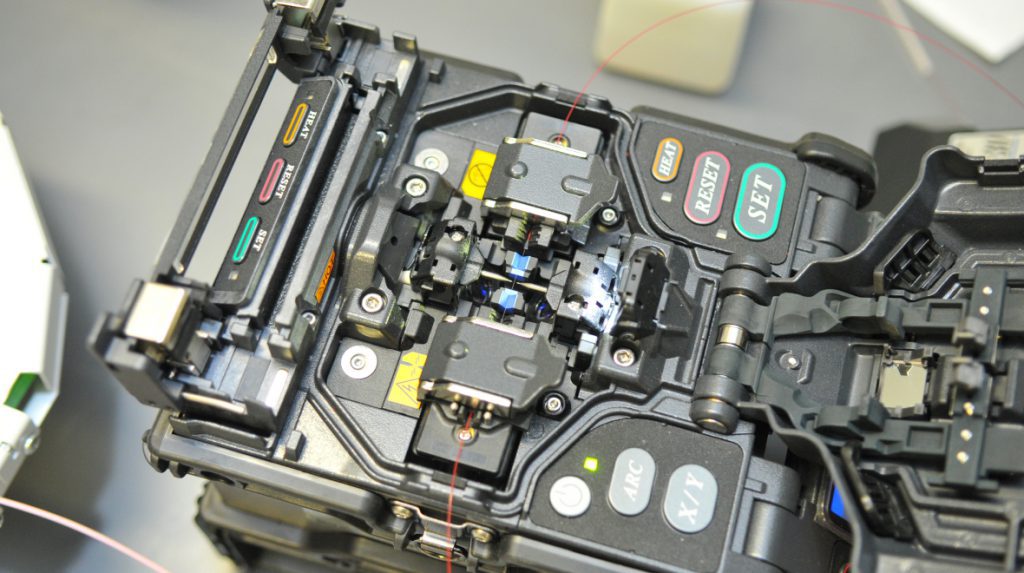

Manufacturing Capabilities

We provide quality-assured assembly of medical and consumer grade devices, integrating optical solutions that range in complexity, size, and form factor to meet your product needs.

Certified Facilities

Our onsite ISO 7 cleanrooms and ISO 8 clean booth provide dust-free environments for development of prototypes and scalable manufacturing of your optical systems to stringent quality standards.

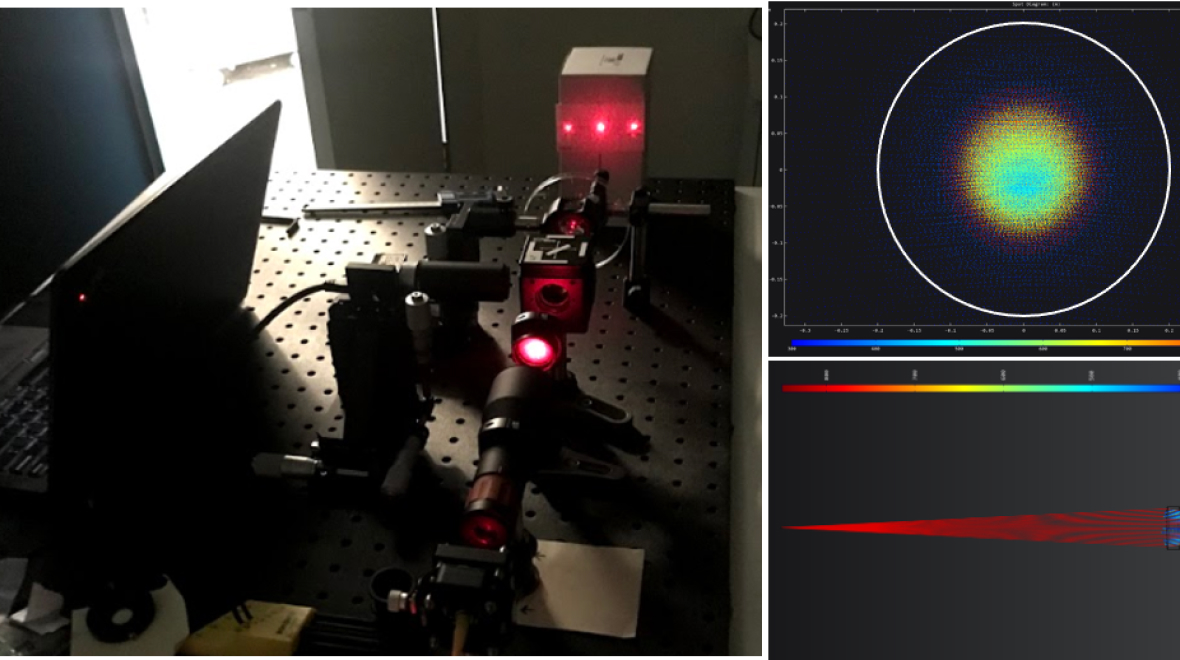

Modelling Capabilities

We offer COMSOL Multiphysics simulations and bespoke optical modelling for your product. Validation and tuning of models are done through empirical testing of prototypes.

- Performance Modelling

- Image Simulation

- Illumination Analysis

- Wave and Ray Tracing

- Custom System Interfaces

- Thermal Optimization

- Materials Selection

Related Capabilities See All Capabilities

We create tailored software solutions for regulated medical environments, leveraging extensive experience in product development and market success. Our team spans the full breadth of software talent (developers, testers, and architects) offering development for a wide range of technological needs, including PC applications, firmware, mobile apps, and cloud.

At our FDA registered and ISO 13485:2016 compliant manufacturing facilities, we can produce anything from low-complexity devices to large floor-standing in vitro and clinical chemistry instruments, in quantities ranging from small batches to high-volume builds.

PI’s electronic engineering team is highly capable in the design of complex electronics for medical devices including: system architecture, schematic & PCB layout using Altium designer, loom design, prototyping, assembly and transfer to manufacture.