Facilities

PI has three offices across the US and Australia with a range of specialist product development and ISO 13485:2016 certified manufacturing facilities for producing regulated medical products.

Irvine, California, USA

Located in Southern California, Irvine is our US headquarters with a purpose-built manufacturing facility and warehouse, as well as engineering and office space.

Box Hill, Melbourne, Australia

Located in Melbourne’s eastern suburbs, Box Hill is our Australian headquarters with three floors of product development, manufacturing, office and collaboration space.

Blackburn, Melbourne, Australia

Just down the road from our Box Hill headquarters, our Blackburn site is a purpose-built manufacturing facility and warehouse.

SPECIALIST FACILITIES

Manufacturing

We have 120,000 sq. ft. of fully-equipped manufacturing space across sites in the US and Australia. The sites are FDA registered and ISO 13485:2016 compliant for manufacturing regulated medical devices. We can produce anything from low-complexity devices to large floor-standing in vitro and clinical chemistry instruments, in quantities ranging from small batches to high-volume builds. PI also manufactures consumables, spares and software.

Cleanrooms

We have two ISO 7 certified cleanrooms to manufacture consumables. We are experienced in processes including solvent bonding, ultrasonic welding, leak testing, air particle testing, heat sealing, gamma sterilization, bioburden and sterility testing.

Cleanbooth

We have an ISO 8 certified process protection booth with HEPA filters to create a dust-free environment with positive air flow. This area is used for assembling and calibrating high-end optical assemblies and instruments.

Wet Labs

Our wet laboratories include a PC2-certified lab where we can test instruments using client chemistries, reagents, samples, and live cells. Having this facility allows us to test the client chemistries with prototypes and pre-production instruments, thereby reducing risk and accelerating development. We also have monitored fridges, freezers, and ultracold storage for client materials.

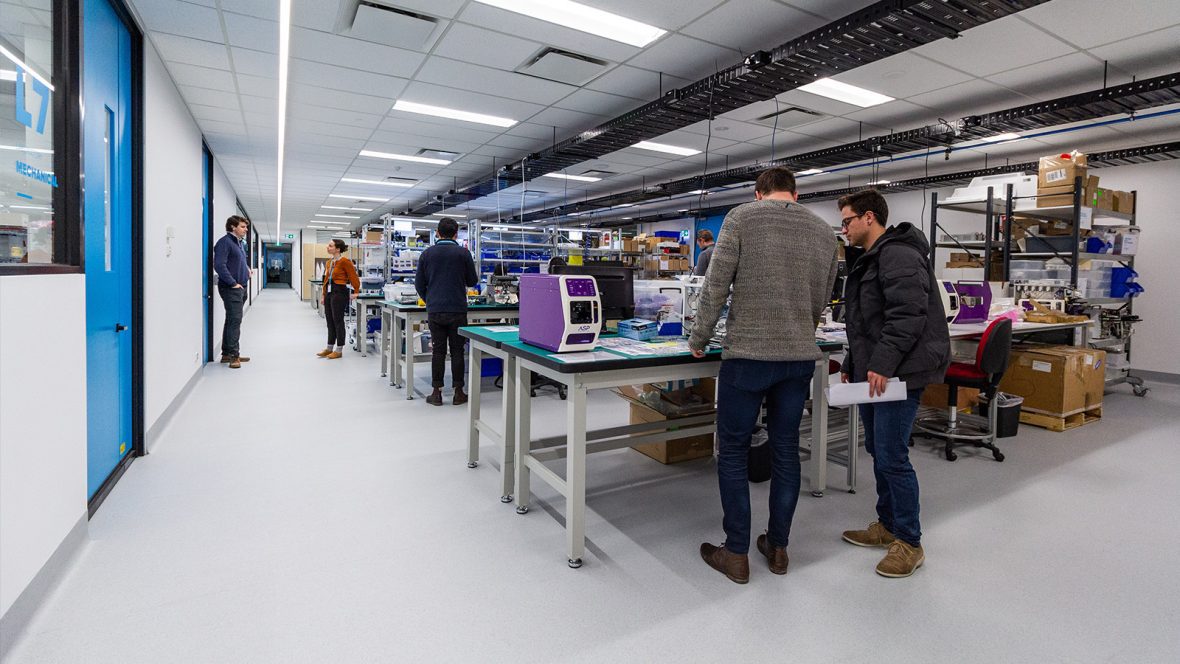

Development Build area

Our purpose-built development build areas provide dedicated spaces to assemble and test instruments from proof-of-principle through to Alpha level. Build areas are at the core of our product development facilities, with easy access to our in-house specialist labs, test equipment, and manufacturing resources.

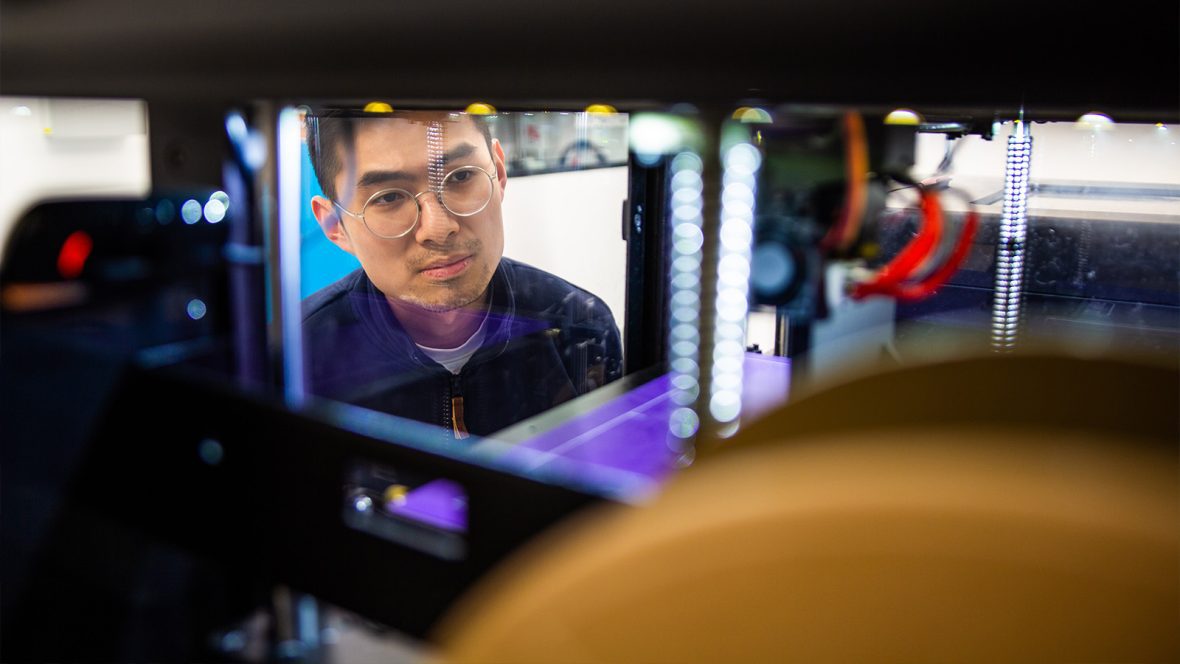

Rapid Prototyping area

Rapid prototyping is a vital tool in early development, particularly for inexpensive and quick testing of design concepts, and PI’s inhouse capability reduces lead times from weeks to hours. We have a wide range of traditional FDM printers, as well as a Nylon Multi Jet Fusion printer for high quality, production level parts to test mechanical functions, and a 50W CO2 laser for cutting sheet goods.

Reliability Lab

When launching a product, it is crucial to have confidence in its reliability to avoid post-launch issues. PI has dedicated reliability labs where we run short or long-term instrument testing in a controlled environment. Our reliability facilities include two environmental chambers for thermal and humidity testing, and a vibration chamber with orbital shaking. Our software and hardware reuse platforms make short work of automating recurring instrument interactions to accelerate reliability programs.

Electronics Lab

We have a purpose-built electronics lab to build prototypes, perform testing, and rework designs. The lab has a large range of soldering equipment and microscopes, as well as an ESD test table, and calibrated ESD gun to perform pre-compliance tests on instruments and identify vulnerabilities early. Other onsite capabilities include making and modifying cable looms, which is critical to rapid prototyping.

EMC Chamber

In the PI Electronics Lab, we have an anechoic chamber for radiated emissions measurements. In this chamber, initial scans of instruments (or sections of an instrument) can be performed to identify problematic frequencies early. The facility also helps with debugging designs if testing at external test houses highlights issues. Among an extensive range of electronics test equipment is a network analyzer, which is used to characterize components, particularly filters for EMC, and for characterizing antenna performance.

Mechanical Lab

Our mechanical workshop is a fully-equipped space for rapid prototyping of mechanical designs and integration with hardware from other disciplines. In the workshop we have tools for metal fabrication including a lathe, manual mill, CNC mill, brake press, band saw and drill press. In this space, mechanical engineers can rapidly iterate designs, ensuring short lead times for design changes and updates.

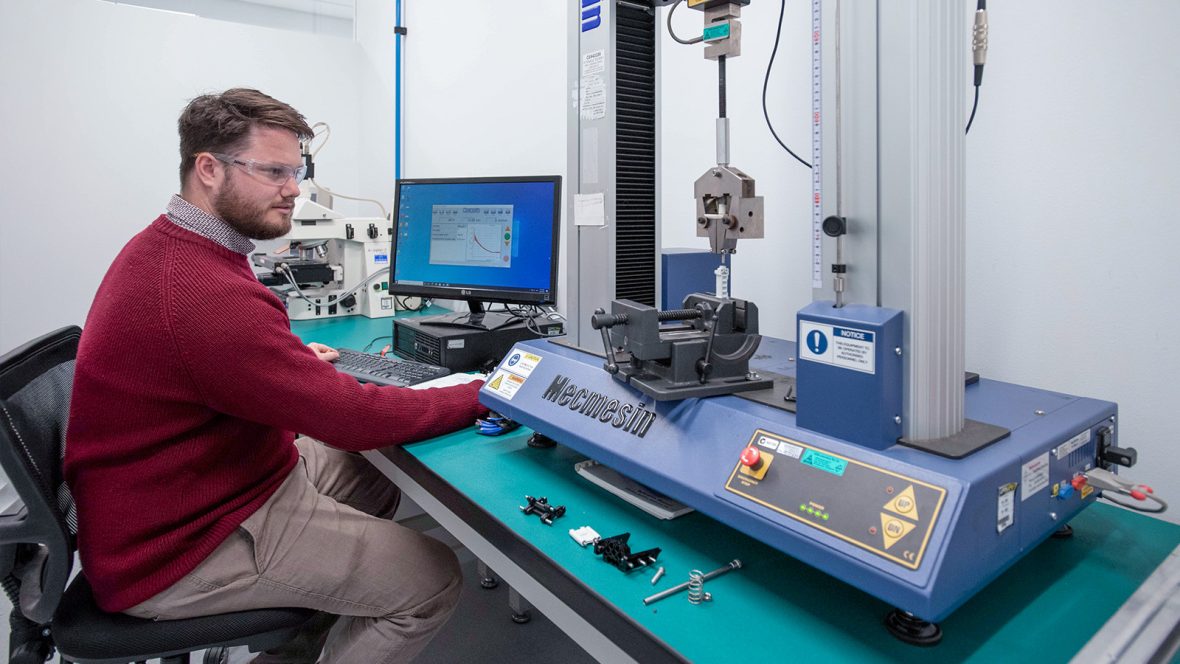

Metrology Labs

PI has a range of metrology tools for verifying the dimensions and physical properties of incoming parts to very fine tolerances and help identify part issues quickly. Our tensile tester enables us to test the strength of parts and identify compressive and tensile stresses or failures. We also have a digital inverted microscope and data logging equipment for temperature, sound, and fluid flow sensing.

Optics Lab

Our dedicated optics lab supports development and testing of prototype and proof-of-principle optical systems, particularly those containing high powered lasers. The lab has an inventory of stock optical and opto-mechanical components for quick turn-around building and testing of optical module concepts. We also have a range of measurement tools such as image quality targets, optical power meters and spectrometers to characterize the performance of modules we develop.

Warehousing

We have warehousing facilities at both our Australian and US manufacturing sites. This gives us more than 30,000 sq. ft. of warehouse space for storing incoming parts and finished products.